Page 1 of 2

It wasn't supposed to be a restoration ....

Posted: Sun Oct 27, 2019 2:42 pm

by axelbaker

Here is a link to the google drive of photos for any one interested

https://drive.google.com/drive/folders/ ... sp=sharing

This year I decided I needed a toy. Not a full on project, but something fun to drive. So I hunted around a bit and found a 1981 Spider.

It was local, clean, and appeared to be as rust free as I was going to find. The previous owner had done a lot of the aestetic stuff. New top, new interior, new paint (that didn't seem to be covering bondo). Tasteful 14 inch wheels. It ran, sorta. The previous owner though it was something to do with sensors.

So it got towed home.

--

So after getting it home I started on little projects to make it road worthy. Most of them were just cleaning up things left from the previous owner. It got a trunk lock (the previous owner only had an ignition key). I started to clean up the engine bay.. Much of the rubber was old and cracking so it got new rubber under the hood, including al the high pressure fuel lines. I don't know why but some jack ass decided to paint the engine, in the car.

As the investigation continued I started to find some interesting wiring "fixes", including some sort of bypass in the started motor. When removed the started motor would run continuously. After some multimetering and poking I found the "sensor problem" the previous owner suspected. Some genous had cut the ECU and spliced it back on by twisting the wires and electrical taping it. There was actually a short from the ECU to the starter, along with all sorts of other stupid. Amazingly the multirelay was brand new. How did that get replaced and the rats nest of wire splices right next to it not get addressed?!

So out came the fuel injection harness. Just a note here, when Bosch doesn't want you to touch things, they usually tell you in some subtle way. They put a plug in it that's hard to remove like in their AFM's or for wiring, they make it all white. So after studying the diagrams and a multi-metering everything, and soldering and heat shrinking, I had a functional harness.

That done and reinstalled, I tried the motor, and low and behold! It runs! Sounds good! Shit! Let's go try to fail SMOG!

Time to fail SMOG! or How to make your Fiat melt.

Posted: Sun Oct 27, 2019 4:10 pm

by axelbaker

Well, that didn't work out how I expected. I figured I would try to get smoged, fail, and have a little list of things go to fix. Nope. Passed!!

Well I guess the next thing to do is take it for a drive. Hmmm 24 Hours of Lemons, Hooptie Con, and Radwood is happening at Sonoma Raceway a friend of mine is taking his Bertone Volvo 242. It's supposed to rain. Italian convertible? Let's go!

Me and the Volvo

Even saw a couple other Fiats

The car ran like a champ.

So lessons learned, contrary to popular belief Italian cars do not melt in the rain, and Radwood is

awesome!

Pandoras Sump

Posted: Sun Oct 27, 2019 5:04 pm

by axelbaker

The trip to Sonoma was a success and I drove around and had some fun with the car. I started looking for classic rallies I could do.

I started replacing some of the missing chrome pieces. I found a shifter extension on EBay with a rotted original knob for cheap. The knob was cracked and rotting and fell appart as soon as I touched it. I had a old MOMO from my last car (a 1987 VW Jetta 14 years ago) I planned to use, but it needed refinishing. For fun I decided to see if I could fix the old knob too. Got out the epoxy and ended up with this, Fiat on the left, MOMO on the right.

This is the moment the car became a project.

My neighbor noticed a small oil leak from the sump. Investigation showed an old JB Weld patch job that was failing. So time to drop the sump. Turns out that's a @!$#%$^ pain!

Well no sooner did that cussing stop when new cussing started. I found this in the sump.

That doesn't belong there I don't think. Time for some research.

Oh, that is half of an auxiliary shaft. That's bad.

While pulling off the sump I also discovered some serious cracking in my engine subframe. More welding.

Well that's a good sized project.

It should work now right? or I've lost my bearings.

Posted: Sun Oct 27, 2019 5:21 pm

by axelbaker

A lot of cleaning, and a little welding later I had a safe subframe. Hole in the sump got some solder as the welder I have access to doesn't really turn down low enough for thin contaminated sheet steel. A few dollars spend and I had a new aux shaft.

And immediately took a cut of wheel to it and performed a preventative lobectomy.

While I am in there the rod bearings got check, a bit ugly, some of the aux shaft went through. New rod bearings are bought. Let's put it all back together.

Wooohoo! She runs! Again!

Knock Knock?

Posted: Sun Oct 27, 2019 5:42 pm

by axelbaker

I finally got a chance to drive around a bit. They brakes were the next thing that needed some love. New fluid, hoses, pads and rotors, ordered. What is this?! Why is there an allen bolt in my caliper where the bleeder belongs. Oh! Some genius stripped it. Hmm, fix or replace? Replace.

BIG Thank you to Vick Setaro, he got me a good rear caliper to rebuild for a very fair price.

Fixed! Wait, no. Leaky master cylinder. Ok, Now it's fixed right? So far so go. Let's go have some fun!

And then my luck ran out. Driving home from Berkeley .... knock knock knock.

Really?!

Oh! This has got to be my fault. I must have installed the bearing wrong ... or ... I dunno.

Experiment time. What if I clean this up and put in the best old bearing. I haven't got anything to loose right?

Clean the oil galleys, one used bearing, new oil, new filter. Run it. Sounds good. Change the oil. Still good, no sparklies in there.

Sweet!

Though ... But what's that sounds?!

Well that experiment didn't work.

Decapitation time.

Posted: Sun Oct 27, 2019 6:23 pm

by axelbaker

Well, I guess the engine is coming apart. Drain fluids, remove radiator, air box, intake manifold, exhaust manifold, and then the head. Well I did want to get the last of that red paint off the engine. Now's the time.

So how bad are things?

Seen worse.

Before

After.

Exhaust guides knurled and reamed back to spec, lapped valve seats, a little JB Weld to fill some minor pitting, light deshrouding of the valves, broke all the sharp edges, polished combustion chambers, and very light clean up of the intake and exhaust runners. That should be good for 0.01 HP

A little better. Amazing what time and fine abrasives and strategic JB weld can do.

Re: It wasn't supposed to be a restoration ....

Posted: Sun Oct 27, 2019 7:01 pm

by 18Fiatsandcounting

Wow, I think the fact that you passed smog and drove around Sonoma Raceway with the engine/car in that condition proves that miracles can in fact occur...!

-Bryan

Re: It wasn't supposed to be a restoration ....

Posted: Sun Oct 27, 2019 7:10 pm

by axelbaker

I actually think the cold and wet is the only reason the engine didn't explode.

Re: It wasn't supposed to be a restoration ....

Posted: Sun Oct 27, 2019 7:59 pm

by rjkoop

Great read so far... Can't wait for the next installment.

Richard

Re: It wasn't supposed to be a restoration ....

Posted: Thu Nov 07, 2019 3:24 pm

by MIGHTY 8

Great reading! Keep the progress coming !

Re: It wasn't supposed to be a restoration ....

Posted: Fri Nov 08, 2019 8:28 am

by nicks

I'm hooked .... who needs TV !

Polishing my rod(s).

Posted: Sun Dec 08, 2019 2:24 pm

by axelbaker

With the head off the pistons came out next. Is the number four con rod bent or ovalized? Time for a lot of measuring. Well, after measuring each the big ends on each rod in 5 places, 5 times, and averaging the measurements, then getting nerdy and doing the math again as RMS, I can say .... they are round to with in less than 0.0005" That is my limit of reliable measurements. The pistons and the rings look good too. I guess it wasn't a rod causing the knock.

Well, the rods are out, might as well....

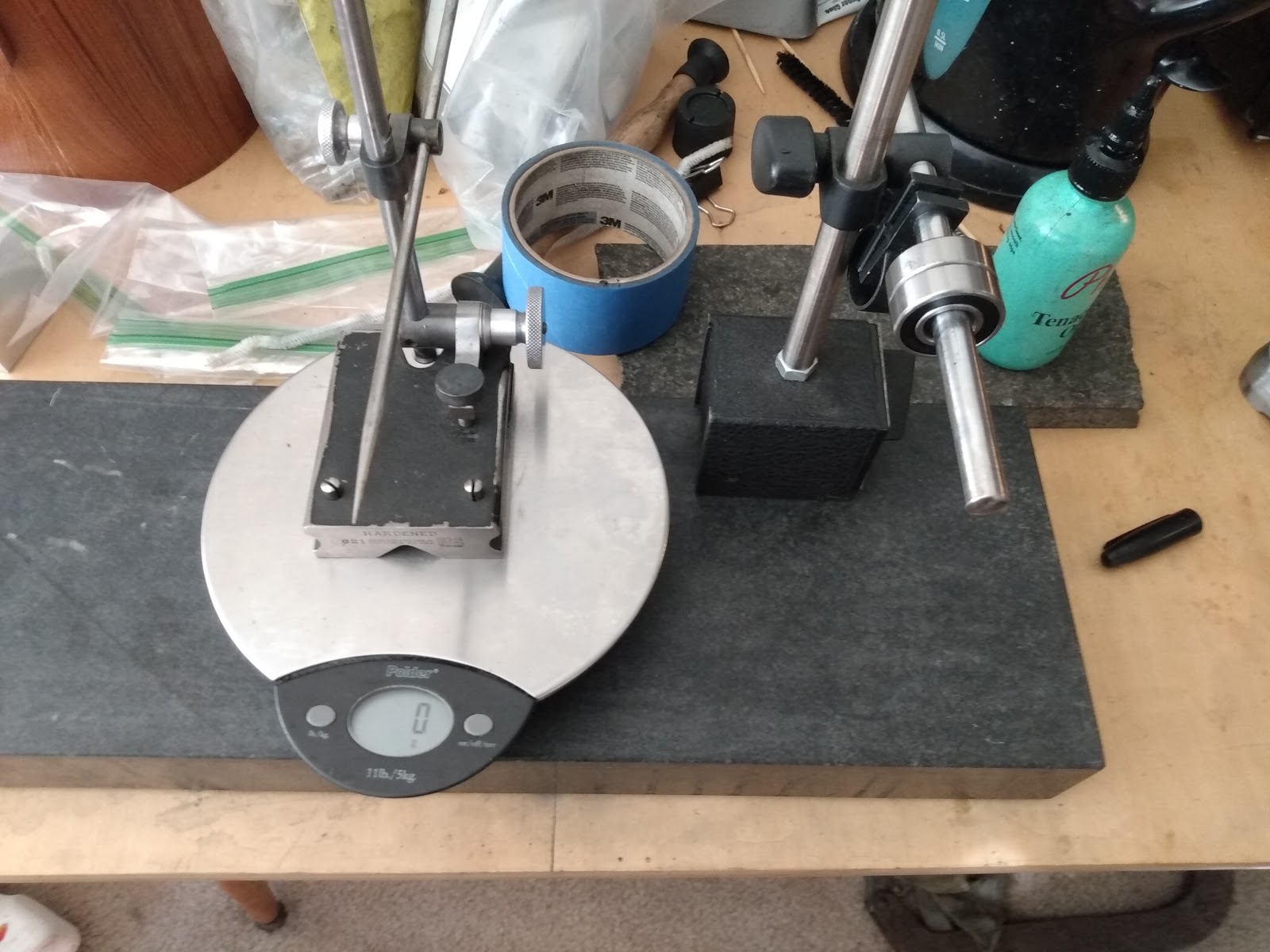

So the connecting rods got their forge lines ground smooth and polished. Then the big and little ends got balanced. I didn't go

too crazy, +/- 1 gram.

My rig to weighing them. The big end goes on the bearings. Worked pretty good.

That should give me another 0.0001 HP.

Join me next time when maybe we finally find out why the motor knocked in the first place.

The smoking gun. Or, I still havn't found what I'm looking for

Posted: Sun Dec 08, 2019 2:47 pm

by axelbaker

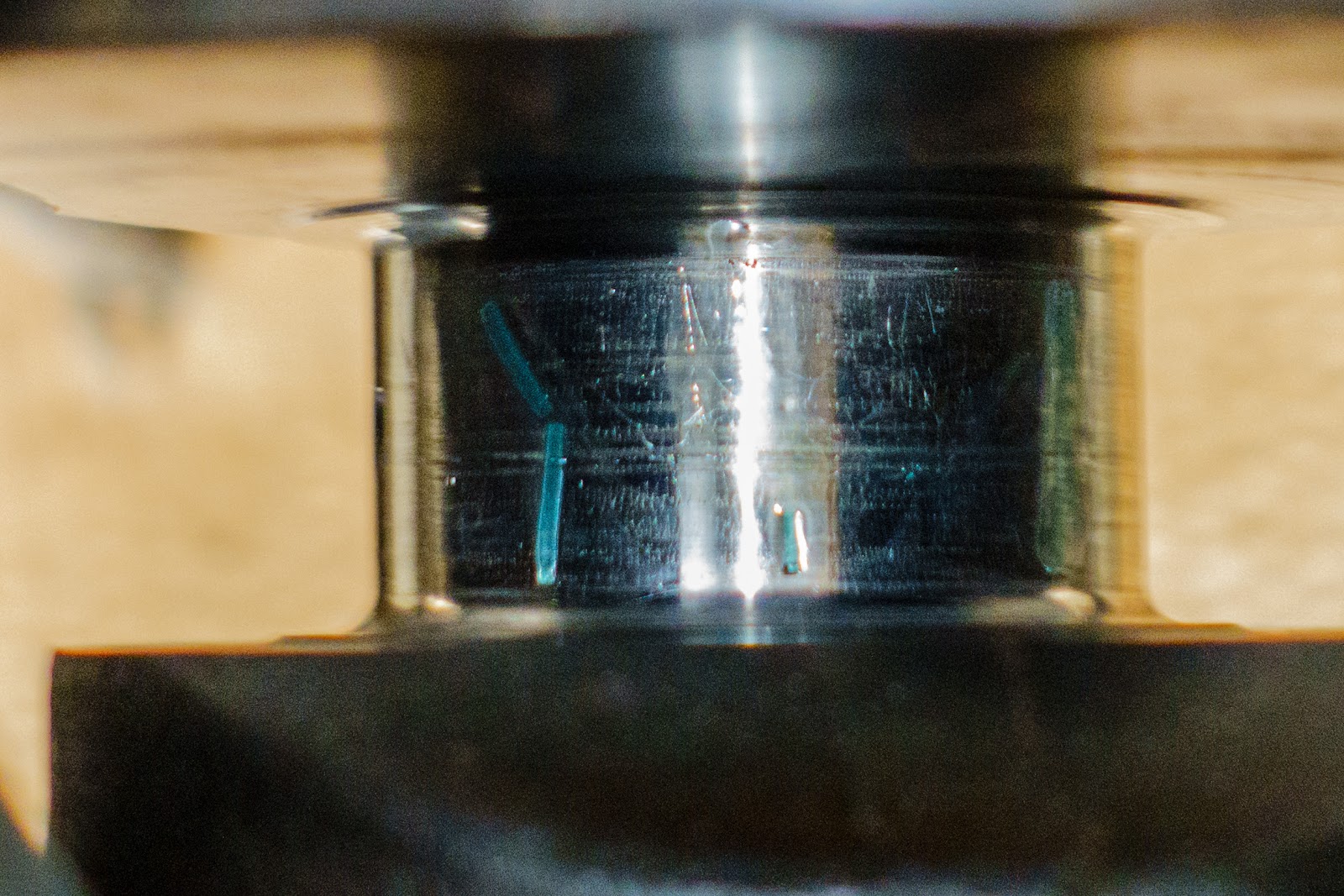

Well, so far everything in the motor has actually looked pretty good. Nothing has been too far out of spec. Nothing actually explains why it was knocking. I guess I better go do more measuring. So more plasticgauge! This time I went for over kill, one piece every 45 degrees on rod pin 4.

Finally!! A SMOKING GUN!! Some thing that is WRONG!!!

As you can see, on the left we have a piece of unsquished Plastiguage, but on the right there is a piece of squished platigauge. If the rod pin on my crank was round they would be squished the same amount. So my crank is F@#ked!

Well there is only one thing to do about that!

Exorcise the demons. Or, Back to the grind.

Posted: Sun Dec 08, 2019 3:24 pm

by axelbaker

So the number 4 rod pin had over 0.006" clearance on the top side. It should be less than 0.003" Every thing else showed no wear at all. The nitriding on the crank has held up wonderfully. Better to preserve it.

Off to my friendly local crankshaft shop to get it welded and reground back to spec. Rather than have the whole thing ground undersized (or just rod pin 4) and loose the surface hardness the nitride provided, I chose to just weld the bad pin and grind it to match the others. As a bonus the weld material should be harder and provide a good wear surface.

Sorry, no pics of the reground crank, but it just looks like a crank.

Now with more measuring!

Posted: Sun Dec 08, 2019 3:54 pm

by axelbaker

Crank back from the shop I measured every thing again. I have been entering everything in to a spreadsheet. I've tried to document everything, all my clearances, weights when it mattered, etc. So now I can confidently say I have 0.002" clearance on my mains, 0.0025" on my rods, 0.002" thrust. This is the first time I've done a bottom end, I am trying to do anything too stupid.

So, more Plastigauge!

And the paint pen. You can see where the crank was ground in this shot.

If any one is in the market, Midwest Bayless had a great price on an Italian made clutch. About $50 less than every one else.

I opted to install the block with out the head. I don't know how other people do it, but I would rather have less weight to swing around. I also like to use a soft sling or rope for things like this where you can scratch things. I still manage to chunk my paint removing and installing the hood. Next time I pull the hood I will blue tape all the edges on both the hood and the car.

Head back on.

In our next installment we will see if the magic smoke stays inside.