Plastic panels were in need of repair:

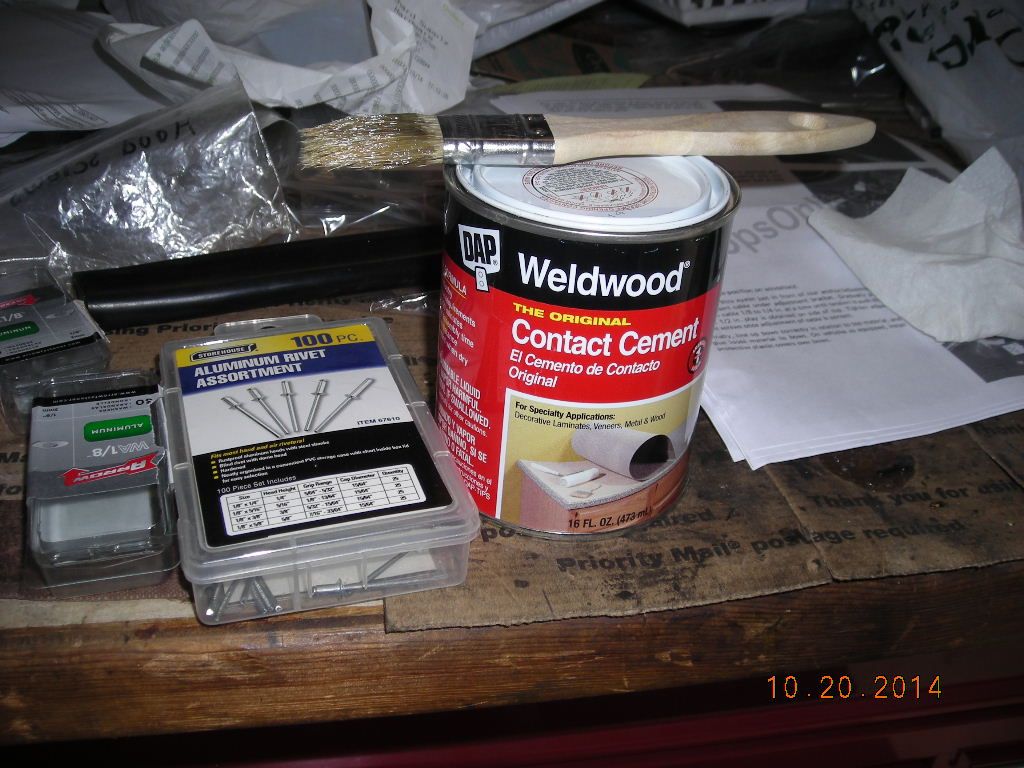

I peeled the vinyl tabs back and sliced off the excess. I kept the exterior side covered to help hold the cracked pieces together. I found using a putty knife and exactor blade the best at removing the hard old contact cement. Then, I wire brushed the back side to remove grime and to give the resin a bit more bite. Cleaned with some acetone. Then covered the holes with clear packaging tape.:

Adding talc to the resin gives it more of a putty consistency. Add some catalyst and I was ready to dribble the filler into the voids. This set up last night:

I used 2 inch web to run the edges (there were small cracks not shown in these photos). Light fiberglass mat to back the panel. Cut and position prior to attempting to add the resin.

For the final coat, you need to add a wax additive. This ensures that the top coat sets up tack free. First, mix the resin, catalyst and wax additive thoroughly. I used a disposable brush; brush the resin onto the edges. Then take your tape pieces and stick them into position. Brush in more resin to satuarate the mat/cloth. Also use the brush to smooth out any bubbles and to make minor cloth adjustments. Next, I added the mat to the entire panel.

When this cures, I'll trim off the rough edges. These will be ready to be re-covered

I haven't done many fiberglass repair projects but encourage anyone on the fence to give it a try. In my area, TAP Plastics has everything you need. Free "How To" pamphlets also.

Warren